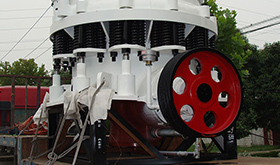

The Introduction of symons cone crusher

The cone crusher is applied to the construction process of crushed stone and machine-made sand, especially when crushing hard materials such as basalt. It is not only efficient, but also has low production cost, and the crushed product has good grain shape and high quality of sand and gravel aggregate..

The Introduction of symons cone crusher

The cone crusher is applied to the construction process of crushed stone and machine-made sand, especially when crushing hard materials such as basalt. It is not only efficient, but also has low production cost, and the crushed product has good grain shape and high quality of sand and gravel aggregate.

Performance advantage:

1, reasonable structure design, small footprint

Three-dimensional structure design, small footprint, advanced technology, high degree of intelligence, simple operation and maintenance

2 ,large breaking force and low operating cost

Low operating cost, low unit energy consumption, large crushing ratio and good crushing effect

3 ,zero noise, no dust pollution

It can effectively ensure low noise and zero pollution in the crushing process, create a good operating environment for the operators, and meet environmental protection standards.

4, selection of good quality and superior performance

Choose a harder material that is durable and has a long service life. In general, the cone crusher is a good choice for efficient crushing.

Production line site:

The Working prinpicle of symons cone crusher

When the cone crusher is working, the rotation of the motor is rotated by a belt pulley or a coupling, a cone crusher drive shaft and a conical crusher conical portion under a urging of the eccentric sleeve. Therefore, the broken wall of the crushing cone is close to and sometimes leaves the surface of the rolling wall fixed on the adjusting sleeve, so that the ore is continuously subjected to impact, pressing and bending in the crushing chamber to realize the crushing of the ore. The motor drives the eccentric sleeve to rotate by the bevel gear, so that the crushing cone rotates. The crushing cone is close to and then leaves the fixed cone to complete the crushing and discharging. The joint between the support sleeve and the frame body is pressed by the spring. When the crusher falls into a non-breakable object such as a metal block, the spring is compressed and deformed to discharge foreign matter, thereby achieving insurance and preventing damage to the machine. The cone crusher realizes the insurance of the cone-type crusher spring insurance system when the non-breakable foreign matter passes through the crushing chamber or the machine is overloaded for some reason, and the discharge port of the cone crusher increases. The foreign matter is discharged from the crushing chamber of the cone crusher. If the foreign matter is stuck in the ore, the clearing system can be used, so that the ore discharge continues to increase, so that the foreign matter is discharged into the crushing chamber of the cone crusher. Under the action of the spring, the cone crusher automatically resets the discharge port, and the cone crusher machine resumes normal operation. The surface of the crushing chamber is covered with a wear-resistant high manganese steel liner. The size of the discharge port is adjusted hydraulically or manually.

| Specification |

Model |

Cavity type |

Max. diameter of

moving cone (mm) |

Discharge

opening (mm) |

Max. feeding

size(mm) |

Power (kW) |

Weight (t) |

Overall

dimensions(mm) |

| 2'FT |

PSGB-0607 |

(F) |

600 |

6-38 |

60 |

22 |

4500 |

2195×1158×1651 |

| 2'FT |

PSGB-0609 |

(M) |

600 |

10-38 |

80 |

22 |

4500 |

2195×1158×1651 |

| 2'FT |

PSGB-0611 |

(C) |

600 |

13-38 |

90 |

22 |

4500 |

2195×1158×1651 |

| 2'FT |

PSGD-0603 |

(F) |

600 |

3.0-13 |

30 |

22 |

4500 |

2195×1158×1651 |

| 2'FT |

PSGD-0605 |

(C) |

600 |

5.0-16 |

40 |

22 |

4500 |

2195×1158×1651 |

| 3'FT |

PSGB-0910 |

(F) |

900 |

9.0-22 |

85 |

75 |

9980 |

2656×1636×2241 |

| 3'FT |

PSGB-0917 |

(C) |

900 |

13-38 |

150 |

75 |

9980 |

2656×1636×2241 |

| 3'FT |

PSGB-0918 |

(EC) |

900 |

25-38 |

150 |

75 |

9980 |

2656×1636×2241 |

| 3'FT |

PSGD-0904 |

(F) |

900 |

3.0-13 |

35 |

75 |

10530 |

2656×1636×2241 |

| 3'FT |

PSGD-0906 |

(M) |

900 |

3.0-16 |

65 |

75 |

10530 |

2656×1636×2241 |

| 3'FT |

PSGD-0907 |

(C) |

900 |

6.0-19 |

85 |

75 |

10530 |

2656×1636×2241 |

| 4.25'FT |

PSGB-1313 |

(F) |

1295 |

13-31 |

115 |

160 |

22460 |

2983×1866×3156 |

| 4.25'FT |

PSGB-1321 |

(M) |

1295 |

16-38 |

178 |

160 |

22460 |

2983×1866×3156 |

| 4.25'FT |

PSGB-1324 |

(C) |

1295 |

19-51 |

205 |

160 |

22460 |

2983×1866×3156 |

| 4.25'FT |

PSGB-1325 |

(EC) |

1295 |

25-51 |

220 |

160 |

22460 |

2983×1866×3156 |

| 4.25'FT |

PSGD-1306 |

(F) |

1295 |

3.0-16 |

54 |

160 |

22590 |

2983×1866×3156 |

| 4.25'FT |

PSGD-1308 |

(M) |

1295 |

6.0-19 |

76 |

160 |

22590 |

2983×1866×3156 |

| 4.25'FT |

PSGD-1310 |

(C) |

1295 |

8.0-25 |

89 |

160 |

22590 |

2983×1866×3156 |

| 4.25'FT |

PSGD-1313 |

(EC) |

1295 |

16-25 |

113 |

160 |

22590 |

2983×1866×3156 |

| 5.5'FT |

PSGB-1620 |

(F) |

1676 |

16-38 |

178 |

220 |

43270 |

3941×2954×3771 |

| 5.5'FT |

PSGB-1624 |

(M) |

1676 |

22-51 |

205 |

220 |

43270 |

3941×2954×3771 |

| 5.5'FT |

PSGB-1626 |

(C) |

1676 |

25-64 |

228 |

220 |

43270 |

3941×2954×3771 |

| 5.5'FT |

PSGB-1636 |

(EC) |

1676 |

38-64 |

313 |

220 |

43270 |

3941×2954×3771 |

| 5.5'FT |

PSGD-1607 |

(F) |

1676 |

5.0-13 |

60 |

220 |

43870 |

3941×2954×3771 |

| 5.5'FT |

PSGD-1608 |

(M) |

1676 |

6.0-19 |

76 |

220 |

43870 |

3941×2954×3771 |

| 5.5'FT |

PSGD-1613 |

(C) |

1676 |

10.0-25 |

113 |

220 |

43870 |

3941×2954×3771 |

| 5.5'FT |

PSGD-1614 |

(EC) |

1676 |

13-25 |

113 |

220 |

43870 |

3941×2954×3771 |

| 7'FT |

PSGB-2127 |

(F) |

2134 |

19-38 |

236 |

400 |

86730 |

4613×3302×4638 |

| 7'FT |

PSGB-2133 |

(M) |

2134 |

25-51 |

284 |

400 |

86730 |

4613×3302×4638 |

| 7'FT |

PSGB-2136 |

(C) |

2134 |

31-64 |

314 |

400 |

86730 |

4613×3302×4638 |

| 7'FT |

PSGB-2146 |

(EC) |

2134 |

38-64 |

391 |

400 |

86730 |

4613×3302×4638 |

| 7'FT |

PSGD-2110 |

(F) |

2134 |

5.0-16 |

89 |

400 |

89500 |

4613×3302×4638 |

| 7'FT |

PSGD-2113 |

(M) |

2134 |

10.0-19 |

113 |

400 |

89500 |

4613×3302×4638 |

| 7'FT |

PSGD-2117 |

(C) |

2134 |

13-25 |

151 |

400 |

89500 |

4613×3302×4638 |

| 7'FT |

PSGD-2120 |

(EC) |

2134 |

16-25 |

172 |

400 |

89500 |

4613×3302×4638 |