The Introduction of symons cone crusher

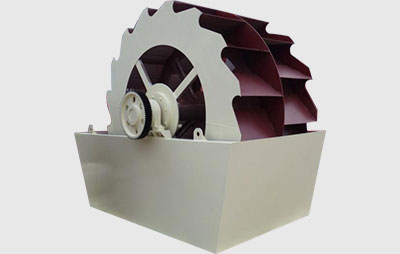

The Bucket wheel sand washer machine is also called the bucket type sand washing machine. The wheel bucket type sand washing machine adopts advanced technology and combines the actual situation of the domestic sand stone industry to develop high-efficiency sand washing equipment. It has less wearing parts, reasonable structure and output. Large, the sand loss during the sand washing process is small, especially the transmission part is isolated from water and sand, so the failure rate is much lower than the current common sand washing machine, which is the best choice for the upgrading of the sand washing industry..

The Introduction of symons cone crusher

The Bucket wheel sand washer machine is also called the bucket type sand washing machine. The wheel bucket type sand washing machine adopts advanced technology and combines the actual situation of the domestic sand stone industry to develop high-efficiency sand washing equipment. It has less wearing parts, reasonable structure and output. Large, the sand loss during the sand washing process is small, especially the transmission part is isolated from water and sand, so the failure rate is much lower than the current common sand washing machine, which is the best choice for the upgrading of the sand washing industry.

The Bucket wheel sand washer machine has the characteristics of simple structure, stable operation, clean sand washing and high output. It is widely used in construction sites, sand and gravel fields, glass factories, power station stations, concrete prefabricated stones and electrical fields.

1. The structure of the machine is simple, and the impeller drive bearing device is separated from the water and the water-receiving material to greatly avoid the phenomenon that the bearing is damaged by water immersion, sand and pollutants.

2. Compared with the traditional spiral sand washing machine, it has obvious advantages when used for sand washing in sand gravel as follows:

b. The machine has almost no wearing parts except the screen.

c. Long service life and no maintenance for a long time.

The Working prinpicle of symons cone crusher

During operation, the motor rotates slowly through the V-belt, reducer and gear, and the impeller rotates slowly. The gravel has a feed trough into the washing tank, which is tumbling under the impeller and grinds each other to remove impurities covering the surface of the gravel. Destroy the water vapor layer of the coated sand to facilitate dehydration; at the same time add water to form a strong water flow, take away the foreign matter with small impurities and small specific gravity in time, and discharge it from the overflow port to complete the cleaning. The clean sand is taken away by the blades, and finally the sand is poured from the rotating impeller into the discharge chute to complete the cleaning of the sand.

| type |

XSD-2610 |

XSD-2816 |

XSD-2900 |

| Impeller specification |

Φ2600×1000 |

Φ2800×1600 |

Φ3000×1600 |

| capacity(t/h) |

20-50 |

30-60 |

50-120 |

| Feed particle size (mm) |

≤10 |

≤10 |

≤10 |

| power(kw) |

5.5 |

7.5-11 |

11-15 |

size

(mm) |

3255×1982×2960 |

3540×3000×2880 |

3845×3000×3080

|