The Introduction of symons cone crusher

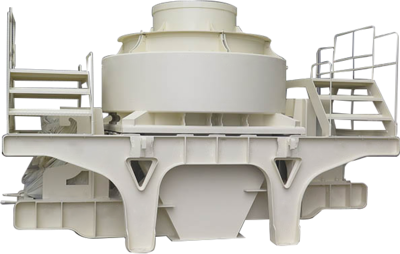

Vertical Shaft Impact Crusher applicable materials include fine crushing of various materials such as river pebbles, limestone, granite, pebbles, construction waste, etc., mainly for the crushing of quartz sand..

The Introduction of symons cone crusher

Vertical shaft impact crusher is widely used in crushing and reshaping of rock and artificial sand making.

Vertical Shaft Impact Crusher has outstanding advantages:

Good quality materials escort

Use American wear-resistant and high-temperature resistant materials to create core components. Use international brands such as Japan, Sweden, and the United States. High degree of protection motor with low selectivity and low noise.

Small parts wear

The upper and lower plates are adjustable to improve the material utilization rate and increase the service life by more than 48%. The combined hammer head only needs to replace the worn hammer head, reducing the use cost by more than 30%. The use of a diamond-shaped impact block increases the impact of the secondary hammer and reduces the damage probability of the vertical plate.

Material throughput

The optimized design of the deep cavity rotor increases material throughput by approximately 30%. The smooth curved design and launch port reduce the flow resistance of the material and greatly improve the material's ability to pass.

Special structure saves labor and effort

Dual-use bulk tray for easy conversion of the two feed modes. Special sealing structure, no oil seal and no oil leakage. Japan's original hydraulic opening device, maintenance and labor saving.

The Working prinpicle of symons cone crusher

Vertical Shaft Impact Crusher working principle

The material can be directly thrown into the rotor after being accelerated by centrifugal acceleration, colliding with the peripheral shield plate, or can be shunted through the bulk disc, part of which is scattered from the surrounding, and the other part enters the rotor to accelerate and then rush out to collide and rub with the surrounding scattered materials, and It collides with the perimeter guard and rebounds to form a circular blow. As the crushing progresses, the small particle material gradually forms a material layer curtain near the perimeter guard plate, which improves the crushing effect and protects the equipment, and the finished product conforming to the specification is discharged from the lower discharge port.

| Model |

Capacity |

Max. feeding size |

Rotating speed

(r/min) |

Power of double motor

(kW) |

Overall dimensions

(mm) |

Weight (t) |

Voltage (v) |

Feed at center and at sides

(tph) |

Feed at center (tph) |

Feed at center and at sides

(mm) |

Feed at center (mm) |

| VSI-7611 |

120-180 |

60-90 |

35 |

3 |

1700-1890 |

110 |

3700×2150×2100 |

11.8 |

380V |

| VSI-8518 |

200-260 |

100-130 |

40 |

35 |

1520-1690 |

180 |

4140×2280×2425 |

14.5 |

380V |

| VSI-9526 |

300-380 |

150-190 |

45 |

40 |

1360-1510 |

264 |

4560×2447×2778 |

17.8 |

380V |

| VSI-1140 |

450-520 |

225-260 |

50 |

45 |

1180-1310 |

400 |

5000×2700×3300 |

25.6 |

380V |