The Introduction of symons cone crusher

hydraulic cone crusher is upgraded on the basis of the traditional spring cone crusher. It can be used in the processing of mining, metallurgy, construction, chemical, electric power, highway and other raw materials..

The Introduction of symons cone crusher

The hydraulic cone crusher is a CFTC combined with advanced technology. It is upgraded on the basis of the traditional spring cone crusher. It can be used in the processing of mining, metallurgy, construction, chemical, electric power, highway and other raw materials. It is a medium and fine crushed hard material. Typical representative, the machine is advanced in technology and stable in performance, and is popular among users.

The hydraulic cone crusher is a relatively advanced technology that can be used to treat crushing operations such as quartz stone, limestone, copper ore, river pebbles, bluestone, granite, etc., and is used in the construction of roads, railways, bridges, airports, buildings, etc.

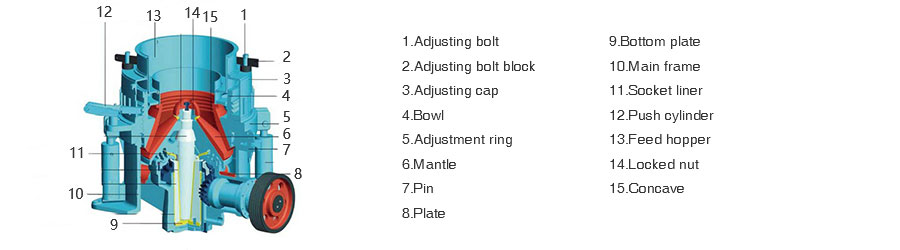

The structural components of the hydraulic cone crusher are mainly composed of fixed cone, moving cone, eccentric sleeve, transmission, frame, adjustment ring, feed bin, discharge port, lock protection cylinder, fan, motor and hydraulic.

Since the hydraulic cone crusher is developed on the basis of the spring cone crusher, its structural components have many similarities with the traditional spring cone crusher. The difference is that the original spring combination is replaced by a safety cylinder through multiple The hydraulic pressure protects the multi-cylinder device, so that the equipment can be fully broken and the crushing force is large.

The Working prinpicle of symons cone crusher

working principle :

When the hydraulic cone crusher is working, it makes a swinging motion along the inner surface, and the material is pressed and bent close to the moving cone to achieve the crushing effect. The crushed material is subjected to gravity, descending from the cone, and continuously rotating in sequence. Broken, locking protection cylinder is used for over-iron protection and cleaning of the crushing chamber. The two hydraulic cylinders are equipped with a buffer accumulator. During the crushing process, the adjustment ring is not affected by a few hard materials.

| Model |

Cavity type (mm) |

Standard type |

Short head type |

Power (kW) |

Capacity (tph) |

| Feed opening (mm) |

Min.discharge opening (mm) |

Feed opening (mm) |

Min.discharge opening (mm) |

| HPM200 |

(EC) |

/ |

/ |

/ |

/ |

132-200 |

90-250 |

| (C) |

185 |

19 |

76 |

10 |

| (M) |

125 |

17 |

54 |

6 |

| (F) |

95 |

13 |

23 |

6 |

| (EF) |

0 |

0 |

10 |

5 |

| HPM300 |

(EC) |

230 |

25 |

|

|

180-250 |

115-440 |

| (C) |

210 |

20 |

75 |

75 |

| (M) |

150 |

15 |

2--19 |

50 |

| (F) |

105 |

10 |

20 |

20 |

| (EF) |

/ |

/ |

20 |

20 |

| HPM400 |

(EC) |

295 |

30 |

/ |

/ |

280-355 |

140-630 |

| (C) |

250 |

25 |

90 |

10 |

| (M) |

195 |

20 |

50 |

8 |

| (F) |

110 |

14 |

40 |

6 |

| (EF) |

|

|

30 |

6 |

| HPM500 |

(EC) |

330 |

30 |

/ |

/ |

355-450 |

175-790 |

| (C) |

285 |

25 |

90 |

13 |

| (M) |

200 |

20 |

55 |

10 |

| (F) |

133 |

16 |

40 |

8 |

| (EF) |

/ |

/ |

35 |

6 |

| Model

|

Open circuit closed discharge(mm)

|

| t/h |

10(mm) |

13(mm) |

16(mm) |

19(mm) |

22(mm) |

25(mm) |

32(mm) |

38(mm) |

45(mm) |

51(mm) |

| HPM200 |

t/h |

90-120 |

120-150 |

140-180 |

150-190 |

160-200 |

170-220 |

190-235 |

210-250 |

210-250 |

210-250 |

| HPM300 |

t/h |

115-140 |

150-185 |

180-220 |

200-240 |

220-260 |

230-280 |

250-320 |

300-380 |

350-440 |

|

| HPM400 |

t/h |

140-175 |

185-230 |

225-280 |

255-320 |

275-345 |

295-370 |

320-430 |

360-490 |

410-560 |

465-630 |

| HPM500 |

t/h |

175-220 |

230-290 |

280-350 |

320-400 |

345-430 |

365-455 |

405-535 |

445-605 |

510-700 |

580-790 |