The Introduction of symons cone crusher

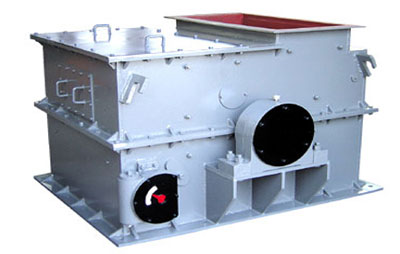

The Ring hammer coal crusher is a new type of crushing machine. Suitable for crushing brittle, medium-hard, and low water content. In the building materials, metallurgy, chemical, and thermal power generation industries, it is mainly used for crushing coal, coal gangue, sandstone, shale, limestone, gypsum and other minerals. .

The Introduction of symons cone crusher

The Ring hammer coal crusher is a new type of crushing machine. Suitable for crushing brittle, medium-hard, and low water content. In the building materials, metallurgy, chemical, and thermal power generation industries, it is mainly used for crushing coal, coal gangue, sandstone, shale, limestone, gypsum and other minerals. The ring hammer crusher has the characteristics of stable operation, reliable, long service life, compact structure, less dust, low noise and strong ability to discharge super-hard materials.

Main purpose of ring hammer crusher

The main working part of the ring hammer crusher is a rotor with a hammer. The rotor consists of a main shaft, a disc, a pin and a hammer. The motor drives the rotor to rotate at high speed in the crushing chamber. The material is fed into the machine from the upper feed port, and is crushed by the impact, impact, shearing and grinding action of the high-speed moving hammer. In the lower part of the rotor, a sieve plate is arranged, and the size of the pulverized material smaller than the mesh size is discharged through the sieve plate, and the coarse-grained grade larger than the mesh size is retained on the sieve plate and continues to be struck and ground by the hammer, and finally passed through the sieve plate. Exhausted from the machine.

The Working prinpicle of symons cone crusher

Ring hammer crusher working principle

The main working component of the ring hammer coal crusher is a rotor with a ring hammer. The rotor consists of a ring hammer shaft and a ring hammer. The motor drives the rotor portion to rotate at a high speed in the crushing chamber. The material to be crushed is transported from the upper feed port to the machine, and is broken by the impact of the high-speed rotary motion ring hammer and the collision, extrusion and grinding between the materials. Below the rotor part, a raft is provided, and the broken grain size of the material smaller than the boring plate hole size is eliminated by the slab plate, and the material granularity larger than the boring plate hole size continues to be hit by the ring hammer, and finally passes through the slab elimination machine. outer

| Type |

Rotor length (㎜) |

Maximum feed block (㎜) |

Discharge granularity (㎜) |

capacity(t/h) |

size(㎜) |

weight(kg) |

| PCH-0402 |

400×200 |

200 |

≤30 |

8-12 |

800*890*560 |

800 |

| PCH-0404 |

400×400 |

200 |

≤30 |

16-25 |

980*890*570 |

1050 |

| PCH-0604 |

600×400 |

200 |

≤30 |

22-33 |

1030*1270*800 |

1430 |

| PCH-0606 |

600×600 |

200 |

≤30 |

30-60 |

1350*1270*820 |

1770 |

| PCH-0808 |

800×800 |

200 |

≤30 |

75-105 |

1750*1620*1080 |

3600 |

| PCH-1010 |

1000×1000 |

300 |

≤30 |

160-200

200-245 |

2100*2000*1340 |

6100 |

| PCH-1016 |

1000×1600 |

300 |

≤30 |

300-350

400-500 |

2700*2000*1350 |

9200 |

| PCH-1216 |

1200×1600 |

400 |

≤30 |

500-620

620-800 |

3100*2800*1750 |

15000 |

| PCH-1221 |

1210×2100 |

400 |

≤30 |

800-1000 |

3620*3350*1950 |

24000 |