The Introduction of symons cone crusher

The PC series hammer crusher achieves crushing by the collision of high-speed rotating hammer head and stone and the collision between materials. .

The Introduction of symons cone crusher

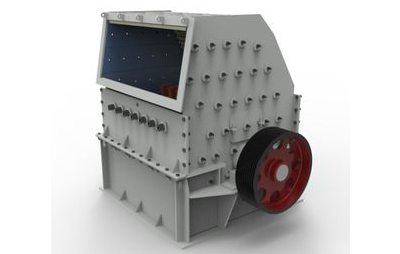

PC hammer crusher introduction:

The PC series hammer crusher achieves crushing by the collision of high-speed rotating hammer head and stone and the collision between materials. The hammer crusher has the characteristics of simple structure, high efficiency and high output. PC hammer crushers are widely used in dry and wet crushing, medium and low hard material crushing (such as coal, limestone, etc.), mining, cement, coal, metallurgy, building materials, road construction, petroleum and chemical industries.

The Working prinpicle of symons cone crusher

PC hammer crusher working principle:

The hammer disc of the PC hammer crusher is driven by the motor to drive the hammer head to make a high-speed circular motion. When the material enters the crushing chamber, it is hit by the high-speed rotating hammer, and the material hits the counterattack after high-speed shot. The friction between the high-speed flying materials is broken and the material that meets the particle size requirements is discharged from the specified sieve holes. After one crushing, the material whose particle size does not meet the requirements is broken again by the hammer with the new material. When the extra large material enters the crushing chamber, the pre-positioned strip is blocked in the upper part of the crushing chamber, and is broken into small and medium-sized materials and then falls into the lower crushing chamber to prevent damage to other working parts due to large material entering the load load. It is broken and safer and smoother.

PC hammer crusher performance characteristics:

PC hammer crusher combines the advantages of counterattack and hammer. It has reasonable structure, stable performance, large crushing ratio, uniform discharge, good particle size, high output, low consumption, easy maintenance, less wearing parts, especially for limestone. In the middle, the fine crushing step is in place, replacing the traditional secondary crushing process, infrastructure construction and equipment investment, the supporting vibration feeder does not need manual operation, and the output is high and cost-saving.