The Introduction of symons cone crusher

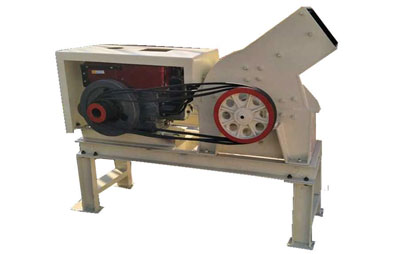

what's the hammer mill price,Find diesel hammer mill in South Africa! the latest diesel hammer mill .Among the many mining equipment in the sand making industry, diesel hammer crusher is the most common type of mineral processing equipment..

The Introduction of symons cone crusher

Among the many mining equipment in the sand making industry, diesel hammer crusher is the most common type of mineral processing equipment, and it is widely used in limestone and other stone production lines. In the current diesel hammer breaking equipment, the hammer is the machine. The core working part is also a fragile part of a whole pulverizing machine. Because the chemical content of some stones is different, the degree of wear on the hammer will not be the same.In addition to the manufacturing process of the hammer, the deployment and working conditions of the mobile hammer crusher in the production process will also have an impact on the life of the hammer.

1- First of all, it is necessary to see whether the work of a hammer sander is reliable. During the impact of the hammer and the material, the hammer must be tightly connected to the rotor.

The hammer is not firmly fixed and the hammer is easily damaged prematurely.

2- In addition to the fixing of the hammer, whether it is convenient and quick to load and unload is also an important indicator to measure its working status, because it is working for a while.

In the future, all parts will wear out. If you can't follow the instructions given by the hammer crusher, it will cause looseness and other reasons.

And the hammer wear is accelerated.

3- Secondly, it is necessary to see if the metal utilization rate of the kanban hammer is reasonable. Because the wear of the hammer is inevitable, a piece of hammer with a certain weight makes it unprofitable.

The use of the smallest quality, that is, the shape of the hammer and the choice of the size of the space is the most worthwhile consideration for the protection of its components.

4- Timely and reasonable deployment of the hammer is also very important. The diesel hammer is unstable in operation and the vibration is large. The main reason is that the original balance condition is destroyed after the hammer is worn.

The Working prinpicle of symons cone crusher

Working Principle

The materials go into the crushing chamber and stack on the middle bracket specially designed in the machine, and the hammer runs in the gap between the middle bracket, and the materials will be continuously crushed and then fall down. The fell small materials will be further crushed by the hammer running with high speed and finally discharged after being screened by the arc grating plate.

| Specifications |

Feeding Size

(mm) |

Discharging size

(mm) |

Capacity

(m³/h) |

Motor power

(kw) |

Total weight

(t) |

Dimensions

(L×W×H)

(mm) |

| PCΦ400×300 |

≤200 |

≤25 |

5-10 |

11 |

0.8 |

900×670×860 |

| PCΦ600×400 |

≤250 |

≤30 |

10-22 |

22 |

2.26 |

1200×1050×1200 |

| PCΦ800×600 |

≤250 |

≤35 |

18-40 |

55 |

4.8 |

1310×1180×1310 |

| PCΦ1000×800 |

≤350 |

≤35 |

25-50 |

75 |

5.9 |

1600×1390×1575 |

| PCΦ1000×1000 |

≤350 |

≤35 |

30-55 |

90 |

8 |

1800×1590×1775 |

| PCΦ1250×1250 |

≤350 |

≤35 |

35-65 |

132 |

14 |

2060×1600×1890 |

| PCΦ1400×1400 |

≤350 |

≤35 |

50-100 |

280 |

32 |

2365×1870×2220 |

| PCΦ1600×1600 |

≤350 |

≤35 |

100-150 |

480 |

37.5 |

3050×2850×2800 |