The Introduction of symons cone crusher

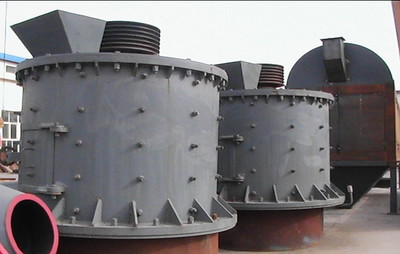

Compound crusher used in various fields such as ore, cement, refractory materials, bauxite clinker, corundum, glass raw materials, etc. It is widely used in the construction of sand, stone and various metallurgical slags. It has high yield efficiency compared with other types of crushers..

The Introduction of symons cone crusher

The Compound crusher is used in mineral processing, coal, building materials, refractory materials, metallurgy, cement, glass, ceramics and other industries.Compound crusher used in various fields such as ore, cement, refractory materials, bauxite clinker, corundum, glass raw materials, etc. It is widely used in the construction of sand, stone and various metallurgical slags. It has high yield efficiency compared with other types of crushers.

Advantages of the

Compound crusher:

1, long life

All parts and frames of the composite crusher are made of high-manganese steel, and the material has a high wear resistance of 3 times that of its material.

2, product granularity

It is suitable for crushing medium and hard materials, and has fine crushing and grinding function, and its product size is even.

3, low operating costs, energy saving

The feeding size is large, the discharge granularity can be adjusted; the process flow is simple, the floor space is small, and the production is saved.

4, long life of accessories

The composite crusher has reasonable structure and reliable operation, and the failure rate is very small from the work, which improves the service life of the equipment.

The Working prinpicle of symons cone crusher

Working principle of Hammer Mill:

Under the action of high-speed centrifugal force, the material falling from the upper part of the machine vertically into the impeller of high-speed rotation and the other part of the material which is divided by the umbrella in the form of umbrella produce high-speed impact and pulverization. After the material impacts, it is in the casing and impeller. The vortex is formed to collide with each other, rubbed and pulverized, and then flushed downward to discharge. Screening equipment controls the finished product size.

| Type |

capacity(t/h) |

power(kw) |

| HM515 |

5-15 |

4p 30kw |

| HM130 |

10-30 |

4p 55kw |

| HM260 |

20-60 |

6p 90kw |

| HM380 |

30-80 |

8p 110kw |

| HM410 |

40-100 |

8p 160kw |